Tel:+86-539-8608719

Mobile:+86 18660900123

whatsapp:+86 18660900123

Email:nancy@baitwood.com

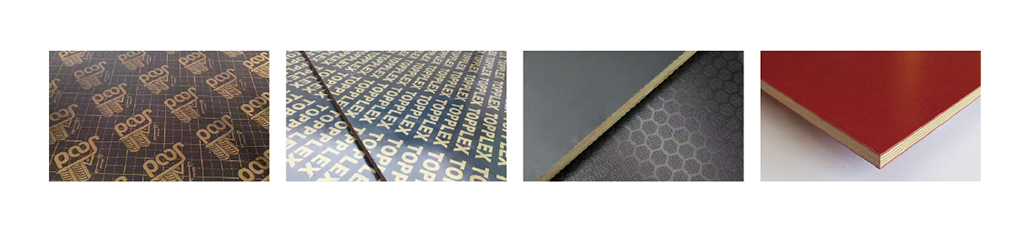

Film Faced Plywood is a durable construction panel coated with phenolic or melamine film on both sides, offering excellent water resistance, wear resistance, and smooth concrete release. It is widely used for concrete formwork and shuttering applications, providing stable performance, repeated reuse, and a high-quality concrete finish under demanding construction conditions.

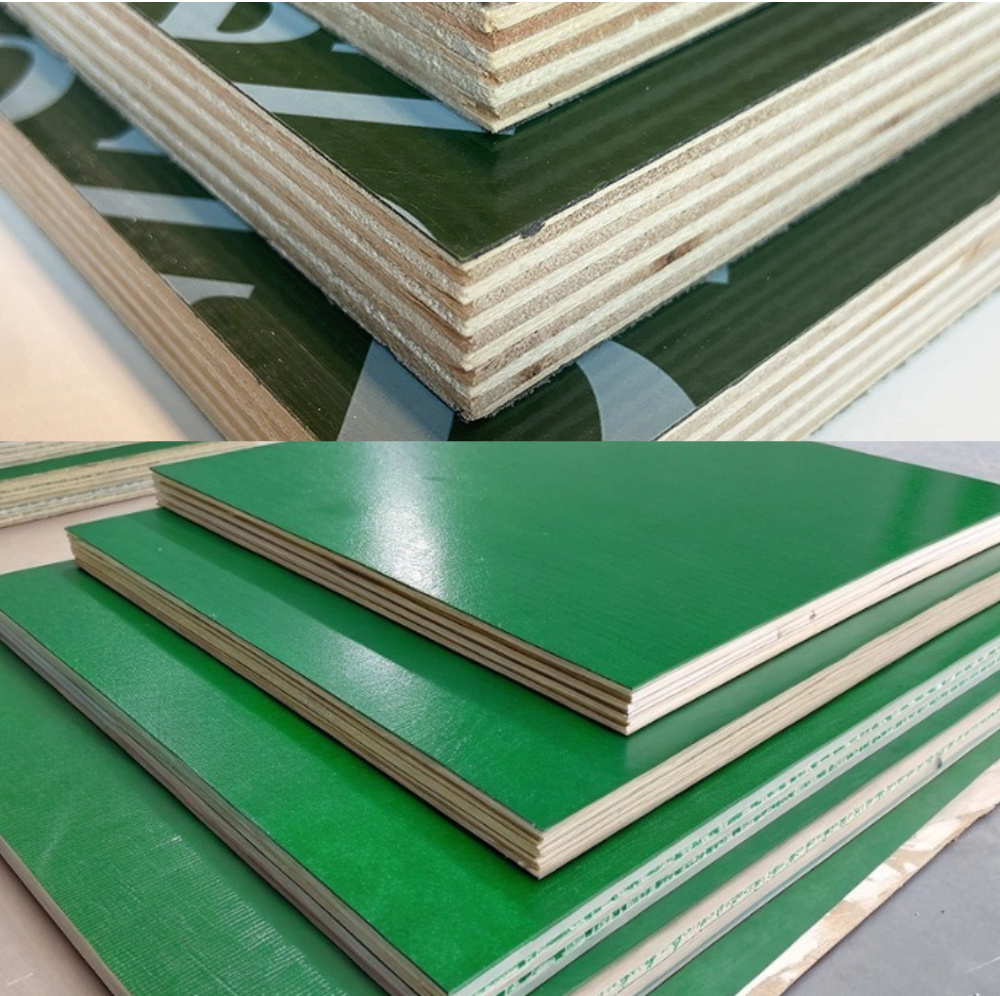

PP Film Faced Plywood is a high-performance construction plywood coated with a polypropylene (PP) film on both surfaces. Designed for heavy-duty use, especially in concrete formwork and shuttering applications, this plywood offers excellent water resistance, durability, and reusability. Compared with traditional phenolic film faced plywood, PP Film Faced Plywood provides smoother surfaces, easier demolding, and longer service life.

PP Film Coating: Polypropylene film creates a smooth, non-stick surface, ensuring clean concrete finishes and easy release.

Excellent Water Resistance: Highly resistant to moisture and water absorption, suitable for repeated use in wet environments.

High Reusability: Can be reused many times without delamination, reducing overall project costs.

Strong Core Structure: Made with quality hardwood, poplar, or mixed cores bonded with WBP glue for superior strength.

Easy Cleaning & Maintenance: Concrete residue can be easily cleaned from the PP surface after use.

Eco-Friendly Option: Reusable material reduces wood consumption and construction waste

| Attribute | Details |

|---|---|

| Application | Apartment |

| Feature | Eco-Friendly |

| Design Style | Modern |

| Technics | Rotary Cut |

| Place of Origin | Linyi, Shandong, China |

| Brand Name | BAITE |

| Product Name | PP Film Faced Plywood |

| Thickness | 1.8 – 25 mm |

| Delivery Time | Within 15 days |

| MOQ | 1 × 40HQ |

Core Walls & Shear Walls: Ideal for smooth, high-quality concrete surfaces in building cores and structural walls.

Columns & Beams: Ensures precise dimensions and excellent finish for load-bearing elements.

Slabs & Decks: Suitable for large-area casting with consistent surface quality.

Bridge Piers & Abutments: Withstands demanding conditions while producing durable concrete surfaces.

Tunnel Linings & Segments: Perfect for curved and customized forming requirements.

Retaining Walls & Sound Barriers: Delivers both structural integrity and aesthetic appearance.

Viaducts & Overpasses: Efficient for repetitive modular construction.

Dam Structures: Excellent water resistance and durability in humid environments.

Power Plants (Thermal, Nuclear, Hydro): Meets strict technical specifications for specialized concrete work.

Water Treatment Facilities: Resistant to chemical exposure and moisture.

Industrial Plants & Warehouses: Cost-effective for large-scale projects with high reusability.

Residential Complexes: Produces ready-to-paint concrete surfaces, eliminating plastering work.

Parking Garages: Efficient for slab and column construction with high turnover.

Architectural Concrete: For exposed concrete structures where surface finish is critical.

Precast Concrete Elements: Excellent for mold making in precast factories.

Curved & Special Shapes: Can be custom-cut for non-standard formwork designs.

We provide one-stop service from raw materials to finished products. Bait Group is located in Linyi, Shandong—one of the largest plywood production

bases in China. Founded in 1998, we have 20+ years of experience in plywood and wood veneer production, with advanced equipment and several

production lines following international manufacturing standards.

Tel:+86-539-8608719

Mobile:+86-18660900123

WhatsApp:+86-18660900123

Email:nancy@baitwood.com

Add:1203-147, NO. 100, LINGONG ROAD,

COMPREHENSIVE FREE TRADE ZONE, LINYI CITY,

SHANDONG PROVINCE, CHINA.

Linyi Bait Wood Industry Co., Ltd ALL RIGHTS RESERVED ©2026