Tel:+86-539-8608719

Mobile:+86 18660900123

whatsapp:+86 18660900123

Email:nancy@baitwood.com

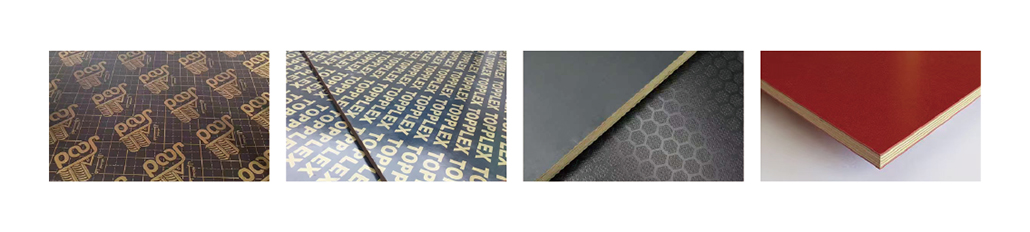

Film Faced Plywood is a high-performance plywood panel coated with a durable, waterproof film on both sides. This protective layer enhances resistance to moisture, abrasion, and chemicals, making it ideal for concrete formwork, construction projects, and outdoor applications. Strong, stable, and smooth, film faced plywood ensures easy handling, excellent load-bearing capacity, and long-term durability. Available in various grades, thicknesses, and sizes, it provides consistent quality for demanding industrial, commercial, and residential projects. Additionally, its reusable and easy-to-clean surface makes it a cost-effective and environmentally friendly choice for multiple construction cycles.

Film Faced Plywood is a high-quality plywood panel coated with a durable film on its surface, providing a smooth, water-resistant, and wear-resistant finish. The film layer enhances the plywood’s durability and makes it suitable for heavy-duty construction, concrete formwork, scaffolding, flooring, and outdoor applications.

Manufactured from selected hardwood or softwood veneers, Film Faced Plywood combines the strength and stability of multi-layered plywood with a protective film surface that resists moisture, abrasion, and chemical exposure.

Durable Film Coating – Smooth, wear-resistant surface that protects against scratches, stains, and moisture.

High Strength & Stability – Multi-layer plywood construction provides excellent load-bearing capacity.

Moisture & Water Resistant – Ideal for wet environments and outdoor applications.

Reusable & Cost-Effective – Can be used multiple times in construction projects without losing quality.

Easy to Work With – Can be cut, drilled, sanded, painted, or laminated according to project needs.

Uniform & Smooth Surface – Ensures high-quality finish for concrete formwork, flooring, and furniture applications.

Environmentally Friendly – Made from responsibly sourced veneers and eco-friendly adhesives.

Water-Resistant & Durable – Film surface prevents moisture penetration and reduces swelling or warping.

Smooth Surface Finish – Ideal for concrete formwork and high-quality finishing.

High Strength & Stability – Multi-layer construction ensures structural reliability under heavy loads.

Reusable & Cost-Effective – Can be used multiple times in construction projects.

Easy to Clean & Maintain – Film coating resists dirt, stains, and chemical damage.

Versatile Applications – Suitable for construction, furniture, flooring, scaffolding, and outdoor projects.

| Attribute | Details |

|---|---|

| Size | 915×2135mm; 1220×2440mm; 1250×2500mm, customized |

| Thickness | 1.5mm – 25mm |

| Grade A | No discolor, No fibre, No hole, No splits |

| Grade B | Slight discolor, small crack, No hole, No fibre |

| Grade C | Medium discolor, Slight pin, bean hole, Light fibre |

| Grade D | Discolor, splits, egg size holes no more than 3 |

| Material | Poplar, Hardwood, Combi, Eucalyptus, etc. |

| Face & Back | Hardwood,Softwood,Marine, |

| Glue | MR, E0, E1, E2, etc. |

| Certification | ISO, CE, CARB, FSC |

| MOQ | 20ft |

Single-Sided Film Faced Plywood

Film coating is applied to one side only; the reverse side remains as bare plywood.

Double-Sided Film Faced Plywood

Film coating is applied to both sides, offering enhanced protection, smoothness, and longer lifespan.

Moisture-Resistant / Water-Resistant Film Faced Plywood

Special adhesive and film make the plywood suitable for wet or outdoor environments.

Heavy-Duty / Commercial Grade

Designed for concrete formwork, scaffolding, and industrial applications requiring high strength and durability.

Flexi plywood Film faced plywood Pine Plywood Okoume Plywood Bintangor Plywood

We provide one-stop service from raw materials to finished products. Bait Group is located in Linyi, Shandong—one of the largest plywood production

bases in China. Founded in 1998, we have 20+ years of experience in plywood and wood veneer production, with advanced equipment and several

production lines following international manufacturing standards.

Tel:+86-539-8608719

Mobile:+86-18660900123

WhatsApp:+86-18660900123

Email:nancy@baitwood.com

Add:1203-147, NO. 100, LINGONG ROAD,

COMPREHENSIVE FREE TRADE ZONE, LINYI CITY,

SHANDONG PROVINCE, CHINA.

Linyi Bait Wood Industry Co., Ltd ALL RIGHTS RESERVED ©2026